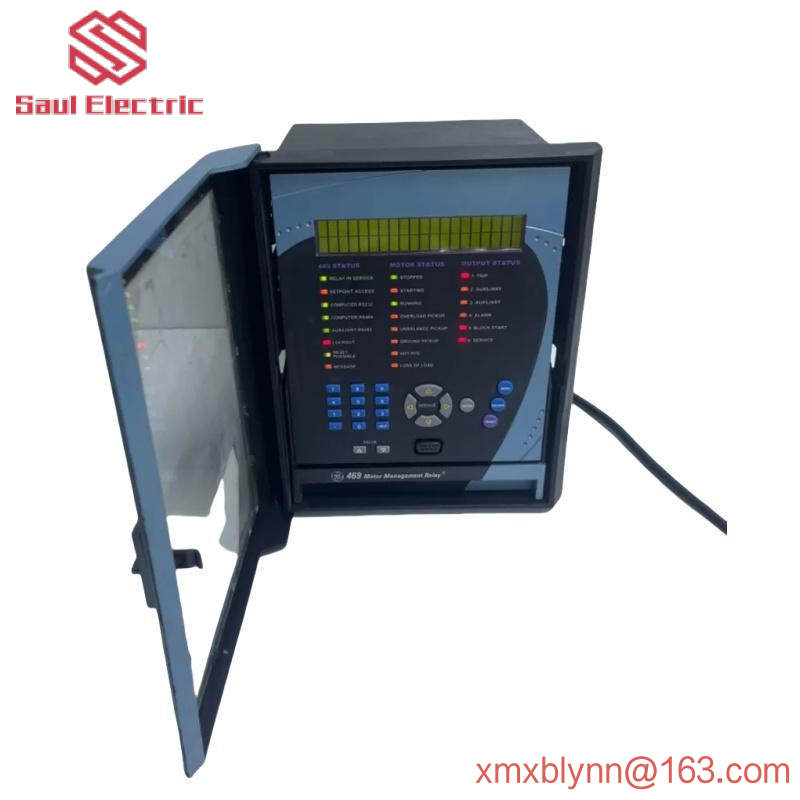

SR489-CASE Generator VanagementRelay

specification

Door type Dustproof door

Extraction type automatic CT short-circuit complete extraction

The IP level is IP10A

Install Configure the 19-inch rack mount or panel

Operating temperature range -40 to 60 degrees Celsius

Seal seal

Transport temperature range -40 to 185 degrees Fahrenheit

The SR489 housing is a companion housing for the generator management relay in the GE Multilin 489 series. This case has a complete pull-out type (automatic CT short circuit), a sealing provision, and a dust door. In this case, the IP level is IP10A. The unit can be mounted on a 19-inch rack or panel. It must be stipulated that the front door can be opened without interference or from adjacent equipment. Press forward firmly to ensure that the front bezel is against the front of the panel and bend the pair of retaining clips outward from each side of the case (to a horizontal position). Once the enclosure is fitted with relays, panel wiring is ready.

Frequently Asked Questions about SR489-CASE

How big of a rack can the chassis of this 489 fit into?

The 489 chassis, or adjacent to another unit in the SR series, can be installed in a standard-sized 19-inch distribution frame.

Why is this box not suitable for this unit?

If an attempt is made to install a mismatched housing, the mechanical key will not allow the device to be fully inserted into the device. Do not force, or you may damage the mechanical key.

How do I remove the device from the case?

First, pull the upper or lower corner on the right to open the lid, hinge on the left. Then position under the handle and press upward with a screwdriver to release the locking handle. Grab the handle and push up until it stops moving up. Finally, pull the device out of the housing and it should slide out freely.