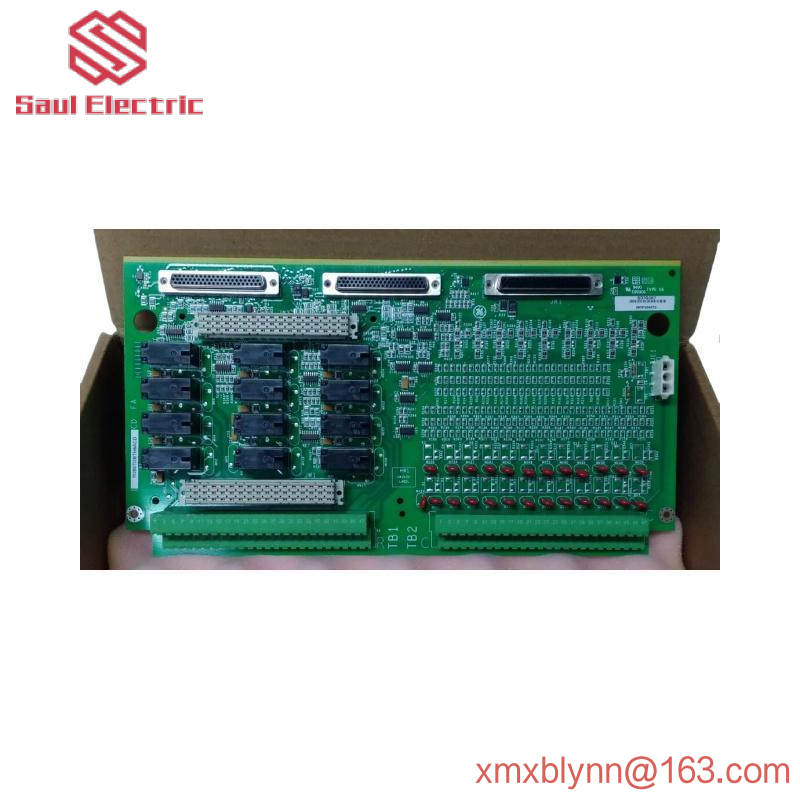

IS200ERIOH1AAA parameter description and IS200JPDDG1AAA industrial control automation scheme gas turbine main control system

The main control system refers to the continuous regulation system of the gas turbine. The single-axis gas turbine control system sets several main control systems that automatically change the FUEL consumption rate of the gas turbine (see Table 11-1) and the corresponding output instructions of each system -FSR(FUEL)

STROKEREFERENCE fuel stroke reference), in addition to the manual control of fuel stroke reference.

The above four IS200TDBTH6ACD, IS200TDBTH6ABC, IS200ERIOH1AAA IS200JPDDG1AAA FSR quantities enter the minimum value selection gate, and select the minimum value of the six FSRS as the output, which is used as the FSR control signal for actual execution at this time.

The start control system only controls the fuel Gf of the gas turbine from the start of ignition until the completion of the start procedure (in the Mark-V system FSRSU is output via the start control system). Fuel requirements vary widely during start-up of gas turbines. Its maximum value is limited by compressor surge (and sometimes by turbine overtemperature), and its minimum value is limited by flameout limit or zero power. This upper and lower limit varies with the gas turbine speed, and the range between these upper and lower limits is narrowest at trip speed.

Leave a comment

Your email address will not be published. Required fields are marked *